Engineering Gallery

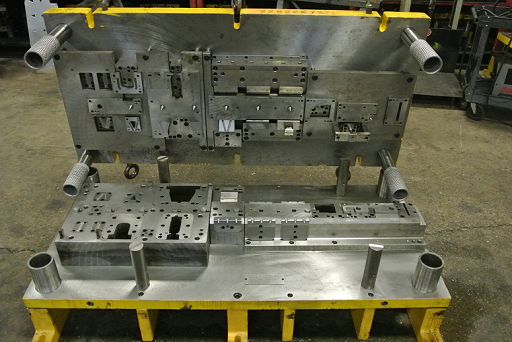

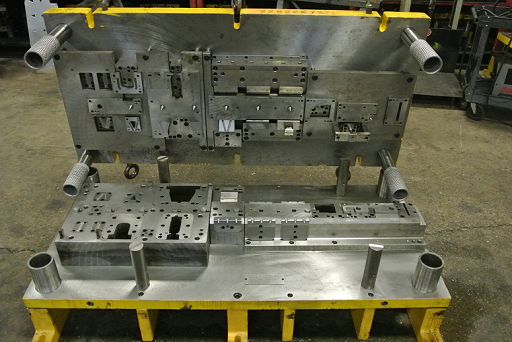

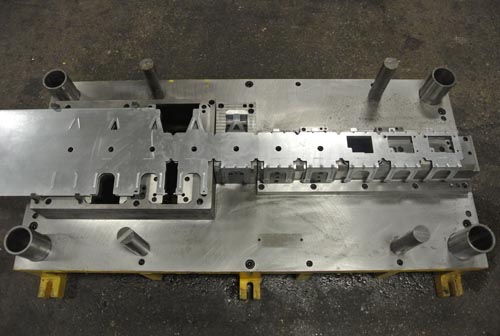

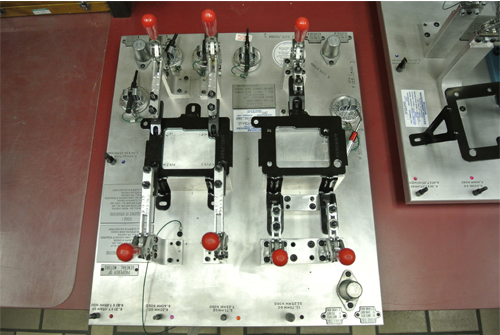

PROGRESSIVE

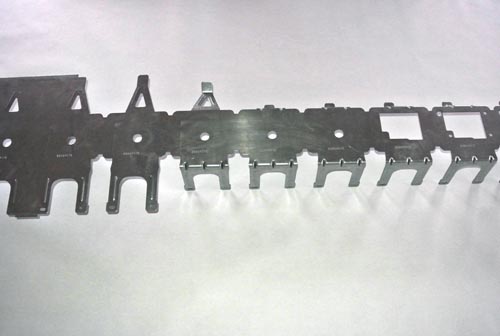

DIE

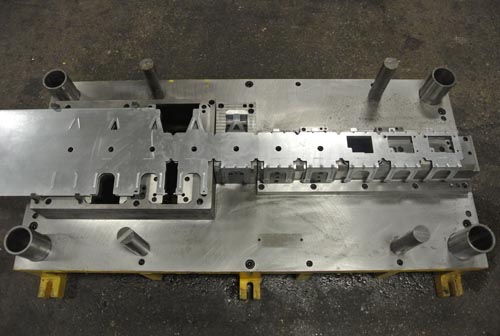

STAGES OF PROGRESSION

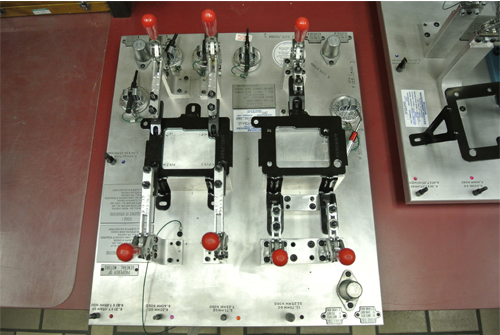

CHECK

FIXTURE

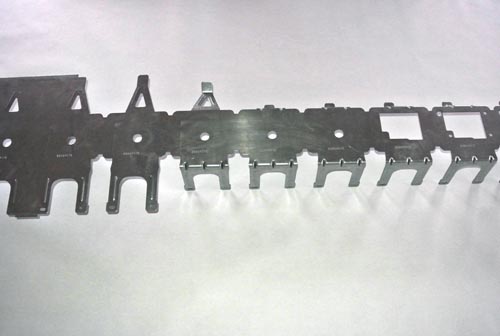

PART STRIP

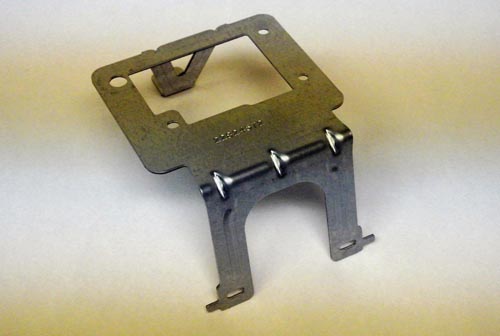

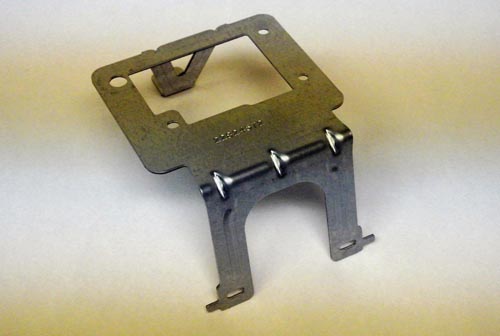

BRACKET

TOOL ROOM

WIRE EMD

MACHINES

CNC MACHINING

CENTER

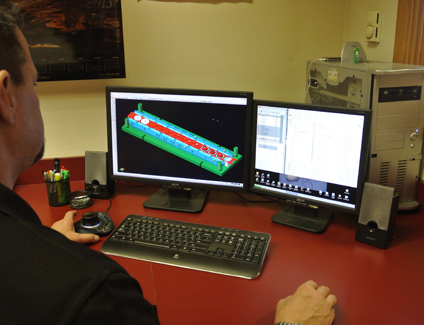

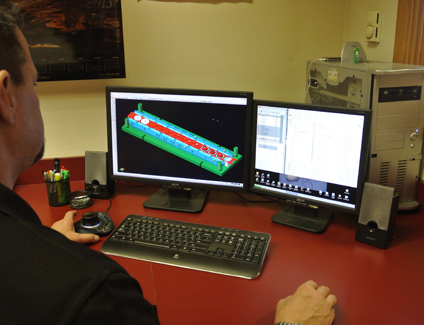

In today’s highly competitive automotive marketplace, Dajaco Industries is an industry-leading company that effectively leverages the combined strengths of our engineering and manufacturing teams to deliver world-class products. Our success is built on our quick completion of the tooling process. Dajaco Industries designs, builds and runs tooling that is customized specifically to our customer’s prototype and production needs. Math data can be translated through UG NX 9, Visi 2017 R2, Teamcenter and Dynaform 5.9.

Ever increasing material prices and operational costs continue to amplify the value of eliminating physical try-outs. Dajaco is able to accurately produce desired stamping results with a minimum number of physical try-outs and prototypes, this helps Dajaco gain an advantage over our competition.

Progressive Die development is a highly collaborative activity requiring effective communication across multiple disciplines including product design, tooling design, manufacturing engineering, industrial operations and production teams.

Ever-increasing requirements for shorter production times are met by leveraging our CAD Software’s specialized planning, design, manufacturing and simulation solutions. This helps Dajaco optimize operational efficiency and reduce time, cost and errors in design, planning and production of sheet metal parts

Dajaco can optimize and validate the full working design of our Progressive Dies long before it is built and installed. Dajaco’s CAD software solutions enable our engineers to eliminate design errors and maintain a quality product through our Progressive Die simulation software. Our specialty equipment includes Wire EDM Machines, CNC Milling Machines, plus Waterjet and Laser Machining Centers for short-run production and prototype development.