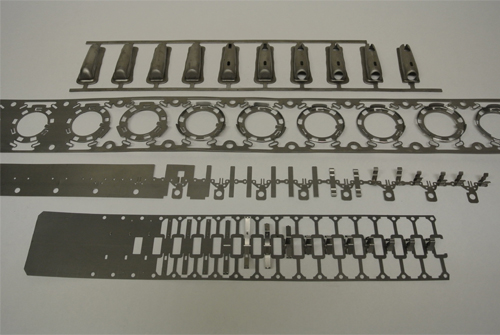

Each station along the path performs one or more specific operation simultaneously each time the die descends until the part is complete. The carrying web is used to transport the partially formed part through each station of the press until it reaches the final station which is typically a cutoff operation.

The cutoff operation separates the finished part from the carrying web, along with metal that is punched away in previous operation and is treated as scrap. With each stroke/cycle of the press, one or more completed parts are cut off and removed from the die.